Before we discuss the difference Ductile Iron vs Cast Iron, let’s make it clear to these two different type of cast iron.

What is Ductile iron?

Ductile iron is a type of cast iron that is known for its strength and durability. It is made by adding magnesium to molten cast iron, which increases its malleability and ductility. This makes it an ideal material for a wide range of applications, from automotive parts to pipe fittings.

Ductile iron is a very strong and durable material, making it ideal for applications that require strength and durability. It is also resistant to corrosion, meaning it can be used in a variety of environments. Its strength and resistance to wear make it a popular choice for automotive parts, such as engine blocks and transmission components.

Ductile iron is also widely used in the construction industry. It is used to create pipes and fittings for water, sewage, and other systems. Its strength and durability make it an ideal choice for these applications. It is also used in the production of manhole covers, which are used to access underground utility systems.

Ductile iron is also popular in the marine industry, where it is used to create propellers, rudders, and other components. Its strength and resistance to corrosion make it an ideal choice for these applications.

What is Cast iron?

Cast iron is a popular material used in many household items, from cookware to furniture and more. It’s a strong, durable metal that has been around for centuries, and it’s still widely used today. Cast iron is made by melting iron ore and other materials together in a furnace. The molten metal is then poured into a mold, where it cools and hardens.

Cast iron is incredibly strong and can last for decades, making it an ideal choice for many applications. It’s also relatively inexpensive, making it a popular choice for those on a budget. Cast iron is also resistant to corrosion, making it a great choice for outdoor items like railings and benches.

One of the most popular uses for cast iron is in cookware. Cast iron pans and skillets are known for their excellent heat retention and even heating, making them great for searing and frying. Cast iron is also non-stick, so you don’t need to use as much oil when cooking.

Another popular use for cast iron is in furniture. Cast iron is often used in outdoor furniture because it’s so durable and resistant to the elements. It’s also a great choice for indoor furniture, as it’s heavy and won’t easily tip over.

Ductile Iron vs Cast Iron

When it comes to metal, there are a lot of options, but two of the most popular are ductile iron and cast iron. Knowing the differences Ductile Iron vs Cast Iron can help you make the right decision for your project.

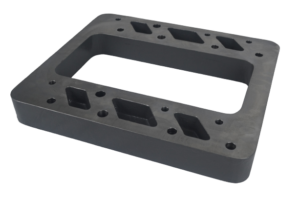

Ductile iron and cast iron are both iron-based metals, but when ductile iron vs cast iron, they have some key differences. Ductile iron is a type of cast iron that has been treated with magnesium or other elements to make it stronger and more malleable. This makes it an ideal choice for many applications, such as pipes, valves, and machine parts.

Cast iron is a much harder metal and is usually used for applications that require more strength and rigidity, such as engine blocks and heavy machinery parts. It is also used for ornamental purposes due to its strength and durability.

One of the key differences between ductile iron and cast iron is their cost. Ductile iron is much more expensive than cast iron, due to the additional processing it requires. However, it is often worth the extra cost, as it is much stronger and more durable than cast iron.

When it comes to corrosion resistance, ductile iron is the clear winner. It has a higher corrosion resistance than cast iron, making it ideal for use in corrosive environments. It is also much more resistant to wear and tear, making it a great choice for applications that require long-term durability.

Berdom is a great choice for anyone looking for a precision machining professional. They have the experience and expertise to get the job done right. Their commitment to quality and customer satisfaction makes them a great choice for any precision machining project. Each casting producing, requires a mold and one wax pattern. It will take more time and separate costs. So it is not a good cost-effective for low quantity products, especially for B2B. As the leader in casting industry, BD machinery are qualified to provide high-quality Automotive casting and Precision casting for you!