Casting Iron

Casting iron is a process that has been used for centuries to create a variety of objects. It is a versatile and cost-effective way to produce a wide range of items, from small components to large structures. The process involves pouring molten iron into a mold, which is then allowed to cool and solidify. The resulting product is an iron casting that can be machined, welded, and used for a variety of applications.

The process of casting iron begins with the selection of a suitable mold. This mold must be able to withstand the extreme temperatures of the molten iron and must be designed to produce the desired shape. Once the mold is ready, the molten iron is heated to a temperature of approximately 1,400 degrees Celsius. The molten iron is then poured into the mold, where it cools and solidifies.

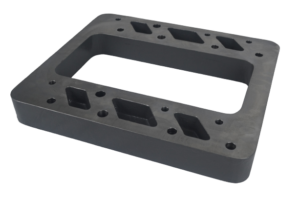

The casting iron process is highly customizable, allowing for a variety of shapes and sizes to be produced. This makes it an ideal choice for a wide range of applications, from small components to large structures. The process is also relatively quick and cost-effective, making it a popular choice for many manufacturers.

The quality of a cast iron product depends on a variety of factors, including the quality of the mold, the temperature of the molten iron, and the speed of the cooling process. It is important to ensure that the mold is of high quality and that the molten iron is at the correct temperature. Additionally, the cooling process should be carefully monitored to ensure that the iron is allowed to cool and solidify at the right rate.

Casting iron is a reliable and cost-effective way to produce a wide range of items. With the right mold and the proper care, the process can produce a high-quality product that is suitable for a variety of applications.

Each casting producing, requires a mold and one wax pattern. It will take more time and separate costs. So it is not a good cost-effective for low quantity products, especially for B2B. As the leader in casting industry, BD machinery are qualified to provide high-quality Automotive casting and Precision casting for you!