Automotive casting and Precision casting is critical in the automotive industry. The manufacturing process for vehicle parts is crucial for the end product’s performance and safety.

One crucial aspect of the production process is it, which involves shaping molten metal into the desired vehicle part.

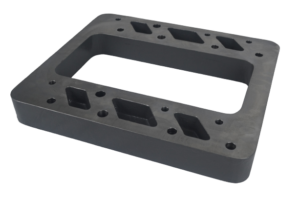

To produce high-quality automotive parts, steel machining is often used. Machining is a process that removes material from a workpiece to achieve the desired shape and size. It is essential for maintaining tight tolerances and producing high-quality parts.

Machining is commonly used in conjunction with casting, as it can be used to refine and finish cast parts to meet the necessary specifications.

When it comes to casting, it is essential to choose a reliable casting foundry. A casting foundry is a facility that specializes in casting metals into specific shapes and sizes.

It is essential to choose a casting foundry that has a proven track record of producing high-quality parts and has experience working with the specific metals required for the desired part.

One type of metal commonly used in casting foundries is cast iron. Cast iron metal is known for its durability and strength, making it an excellent choice for automotive parts.

Cast iron can be used in many different parts, such as engine blocks, cylinder heads, and brake rotors.

Another method of casting that is becoming increasingly popular in the automotive industry is precision casting.

It, also known as investment casting, is a process that involves creating a wax pattern of the desired part, coating it in a ceramic shell, melting away the wax, and pouring molten metal into the shell.

This process allows for intricate and precise designs to be created, with a high level of accuracy and consistency.

When choosing a casting foundry for It, it is essential to choose one that has experience working with this method.

It requires a high level of skill and attention to detail to ensure that the final product meets the necessary specifications.

In conclusion, It is an essential part of the manufacturing process for vehicle parts. Steel machining is often used in conjunction with casting to produce high-quality parts, and choosing a reliable casting foundry is crucial.

Cast iron metal is commonly used in automotive parts, and precision casting is becoming increasingly popular due to its accuracy and consistency.

By understanding the importance of each of these factors, manufacturers can produce high-quality automotive parts that are safe and reliable for drivers.

It refers to the general term for the process of obtaining precision-sized castings.

Compared with the traditional sand casting process, the castings are obtained by precision casting have more precise dimensions and better surface finish. Its products are precise, complex, and close to the final shape of the part.

Can be used directly without processing or processing. It is an advanced process of near-net-shape. And it can be suitable for low quantity request orders.

Automotive casting and Precision casting

It Commonly used is investment casting, also known as lost wax casting. It is widely used for producing ferrous and nonferrous metal casting.

The investment mold is made by using a suitable investment material such as paraffin. The refractory coating and the refractory sand process are repeated on the investment mold.

Hardened shell and dry. The internal melting mold is then melted off to get a cavity. The baked shell is obtained to get sufficient strength.

The residual investment material is burned off and the desired metal material is poured. Solidification, cooling, shelling, sand cleaning.

Thereby obtaining a high-precision finished product. Heat treatment and cold working and surface treatment according to product requirements.

Additionally, in both design and material choice of castings, Precision castings have huge freedom. It allows many types of steel or alloy steel for investment. So on the casting market, It is the highest quality castings.

It also faces a cost of molding and time. Each casting producing, requires a mold and one wax pattern. It will take more time and separate costs. So it is not a good cost-effective for low quantity products, especially for B2B. As the leader in casting industry, BD machinery are qualified to provide high-quality Automotive casting and Precision casting for you!