Common Defect and prevention of metal casting

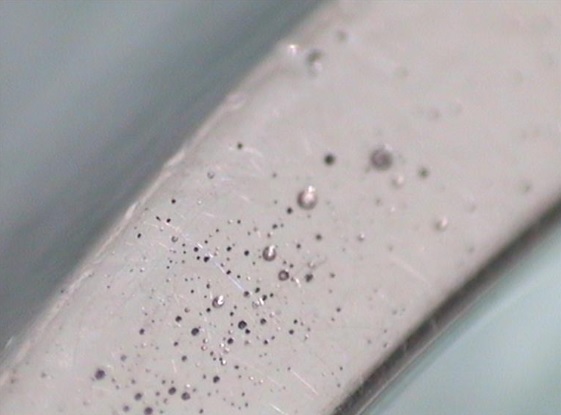

1. Pinhole

Actions to prevent the pinhole happen: It is forbidden to use the contaminated cast aluminum alloy material, the organic compound and the material which has been seriously oxidized. Control smelting process, strengthen the degassing refining. Control the thickness of metallic coatings, which is easy to produce pinhole. Mold temperature should not be too high, the thickness of the casting parts of the use of cooling measures, such as copper block or water, etc.. The strict control of sand water, try to use dry core.

2. Gas porosity

Actions to prevent the gas porosity: Modify the gating system which is not reasonable, the liquid flow smoothly, avoid gas entrapment. Mould and core should be pre – preheating, after coating, must be dry before use. Design mold and core should be considered adequate exhaust measures

3. Oxide slag

Actions to prevent the oxide slag: Strictly controlling the melting process, rapid melting, reducing oxidation, slag removal. Al-Mg alloy must be melted under cover. Furnaces, tools to be clean, and shall not be an oxide, and should be warm, coating should be dry after use. The design of the gating system must have a steady flow, buffer, skimming ability. The liquid flow is stable and no two oxidation is produced by using the inclined gating system. The selection of the coating adhesion force is stronger, the pouring process does not produce the peeling off and into the casting slag formation

4. Hot crake

Actions to prevent the hot crack: the actual pouring system should avoid local overheating, reduce internal stress. Type mold and core angle must be guaranteed in more than 2 degrees, the riser a can be solidified by pumping core mold, when necessary use sand core instead of metal core. Control the thickness of the coating, so that the cooling rate of the casting parts is the same. According to the thickness of the casting mold temperature appropriate choice. Refine the alloy structure, improve the thermal cracking ability. Improvement of casting structure, eliminating angle and wall thickness mutation, reduce hot cracking tendency

5. Shrinkage

Actions to prevent shrinkage: Reasonable riser setting, ensure the solidification, and the feeding capacity. Appropriate reduction of metal mold working temperature. Control coating thickness, thickness of thin wall. Adjust the cooling rate of the metal parts, so that the thickness of the casting has a greater ability to stimulate the cold. Appropriate reduction of metal pouring temperature.